-

- Curve Belt Conveyor

- Vertical Conveyors

- Sorting Machine Series

- Telescopic Belt Conveyor

- Control System

- Chain Conveyor

- Top Chain Conveyor

- Belt Driven Live Roller Conveyor

- Food Packaging Conveyors

- Chain Transfer Conveyor Manufacturer

- High efficiency battery material profess

- Thermoforming Vacuum Packaging Machine

- Continuous lane divider

Introduction of high

efficiency battery material professional conveying equipment

Cobalt lithium Oxide

Manganese

lithium Oxide

Lithium iron phosphate

Ternary

Non metallic materials

(ceramic or engineering plastic materials) are used for the contact parts of

equipment and materials, including non load-bearing screws and bolts: All

equipment is mainly developed and designed for battery materials, suitable for

cobalt lithium oxide, manganese lithium oxide, lithium iron phosphate, ternary

etc materials.

Cobalt lithium Oxide

Manganese

lithium Oxide

Lithium iron phosphate

Ternary

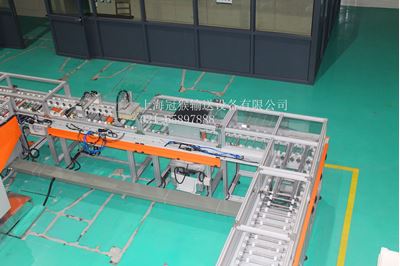

One to two closed-loop outer rail lines One set can supply two kilns operation at the same time

According to the layout of the factory, we can design the automatic conveying scheme of the kiln, improve the production efficiency;and cooperate with the customers to upgrade the original production line

Cobalt lithium Oxide

Manganese

lithium Oxide

Lithium iron phosphate

According to the

requirements of production process and management, independently developed

industrial automation control system; self-made cabinet

Introduce industrial automation control system to improve production management level

Overall design of automatic conveying scheme of kiln

Integrate all kinds of special machines around the kiln, simplify the production process and save the manufacturing cost

Cobalt lithium Oxide

Manganese

lithium Oxide

Lithium iron phosphate

Launch

of the new scheme, the conveyor line is used to integrate the bowl loader,

levelling machine (shaker), grid hole inserting machine, in and out of the kiln

transfer machine, as well as the bowl turner, bowl

Various single machines

Cobalt lithium Oxide

Manganese

lithium Oxide

Lithium iron phosphate

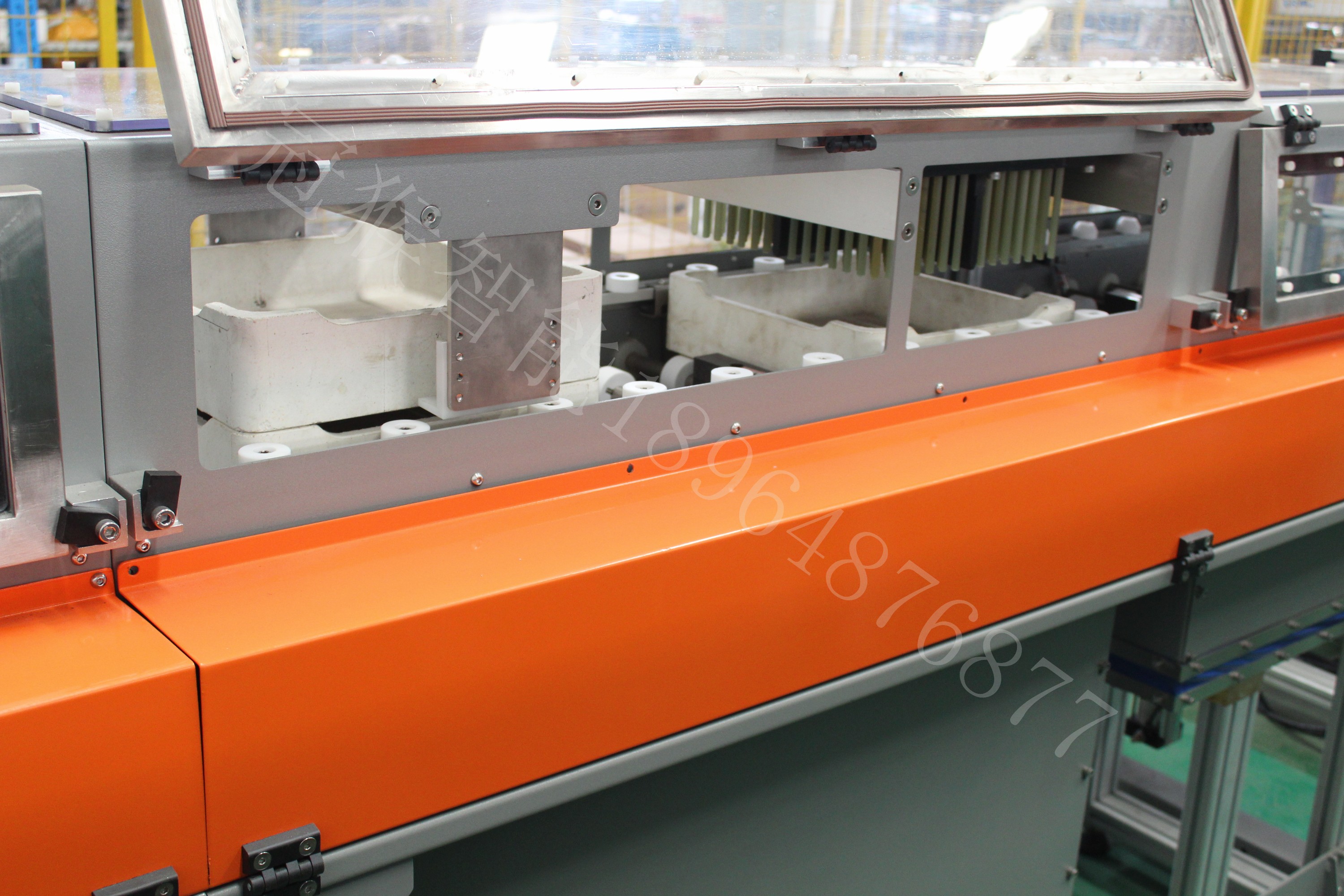

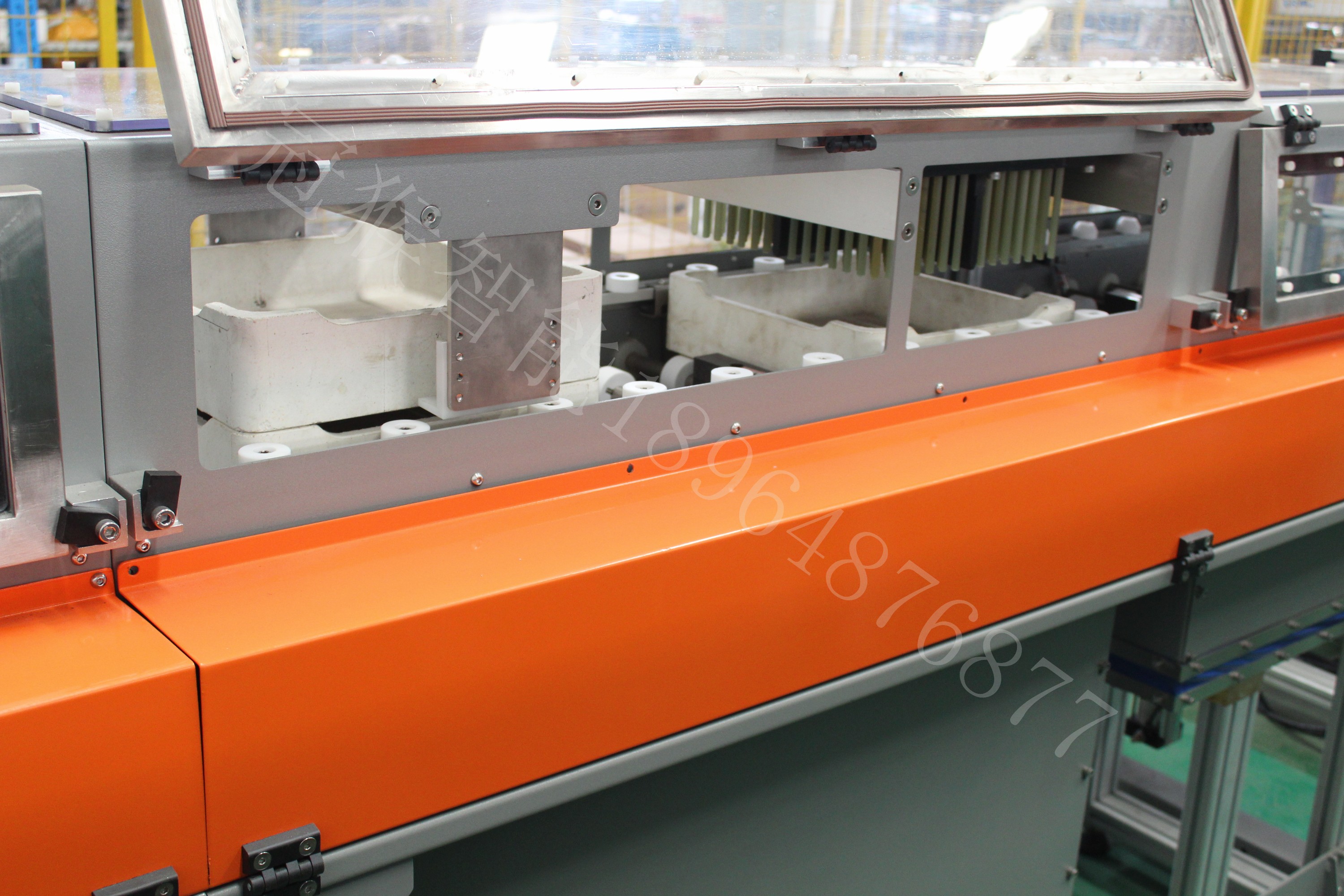

Function:

Double stage filling, quantitative bowl loading, fast speed, saving time

and space

1. The spiral conveyor is used to convey powder to the saggar and

coordinate with the weighing sensor, blocking positioning mechanism, lifting

mechanism, dust-proof mechanism, etc. to realize quantitative weighing

2. The weight can be set on the touch screen, the weight range is 01-100kg,

the accuracy is ± 5-25g according to the parameter setting, and the speed is

15-28s / time.

3. There are two dust-proof gates at the outlet of the spiral pipe, the

front one is butterfly valve, completely sealed; the back one is flapper valve,

the separation space is used to make the powder adhere to the

pipe wall or butterfly valve, and the vibrator is added

4. The design can adopt integral frame with roller conveyor line. The two

end faces of the frame are the same as the end faces of the independent roller

line, i.e. they are connected in the same way as the line.

Full automatic single and double stage bowl loader

Bowl dividing machine

Function:

1. Use

positioning mechanism、 double stroke lifting mechanism

and clamping mechanism, and use the shape of lower open bowl to realize sagger

stacking.

2. Layout inside

the line saves more space

Bowl turner machine

Function:

1.Use positioning mechanism, clamping mechanism, rotating mechanism and realize bowl turning at 180 °degree

2.The turning

speed is 20-30s each time. The turning speed can be adjusted

3 Bowl rotating

driving mechanism: high precision motor rotation, two-way stroke cylinder

rotation

4.The inside of

the bowl turner machine is made of sealing, dustproof, anticorrosive, high

temperature resistant and PA materials

5.The crusher

and loading material container can be connected under the bowl turning machine

Grid / hole inserting

machine

Function

1.

Use pin (insert block) components to cooperate with positioning mechanism,

lifting mechanism, etc. to realize material with holes or slots, which is

favorable for sintering process

2.

Install directly on the line to make full use of space

Mold

can be various: needle punching, cutting block, etc

Integrated machine for filling and shaker flat

and hole inserting and stacking bowls

Function:

The ceramic

roller conveyor line is used to connect the single machine of each station, so

that the kiln and all kinds of transfer machines cooperate to form a

closed-loop transmission.

Bowl

sweeping machine

Function:

Use the rotary brush with

the cross linear module ball screw slide, positioning mechanism and lifting

mechanism etc to clean the inside of the saggar and recover the powder.

Working time: 23 seconds /

time

In and out of kiln transfer

machine

Four

rows bowl transfer machine with synchronous belt

Ceramic

wheel four rows bowl transfer machine

Function:

1. Before entering the

kiln, the saggers shall be arranged in four rows orderly, with a gap of 10 mm.

Eight rows of synchronous belts shall be used to cooperate with the lifting

cylinder, and the saggers shall enter the kiln at the same speed at the same time

for front bin replacement.

2. The transverse

conveying roller line and the transfer machine shall be transmitted by an

integral frame

3. The two (or one)

end faces of the frame are the same as the end faces of the independent roller

line, that is, the same connection way with the line .

Ceramic stacking roller conveyor line

Function:

1. Connect the conveying equipment of single machine in each station, so that the kiln and the tranfer machine can form a closed-loop conveying.

2. Multiple roller shafts (each roller shaft is equipped with 2 ceramic

wheels) drive the rotary roller shaft by motor to make the saggar forward.

3. The roller with adjustable stacking function has obvious advantages

compared with the traditional roller . There is no forced friction between the

ceramic wheel and the saggar to protect the ceramic wheel and the saggar.

Because of the difference of driving structure, the electric control action can

be completed under the condition of continuous operation of the line , so as to

effectively avoid the damage to the motor caused by repeated start and stop. The

continuous operation of the line greatly reduces the bearing capacity of the

motor and the blocking pressure of the cylinder, and the service life of the

cylinder and the motor is greatly extended.

90 degree turn transfer machine

Function:

1. When the sagger is tranmitted at right angles,

it is used for lifting by the synchronous belt and the cylinder.

2. The design of the transfer machine adopts the

integral right angle frame, including two sets of ceramic stacking roller

conveyor lines

3. The two end faces of the frame are the same as

the end faces of the roller line, that is, the connection mode is the same

Contact Us

Jiangsu Guanhou Intelligent Control Equipment Co., Ltd.

Shanghai Guanhou Conveying Equipment Co., Ltd.

Add: Qutang Industrial Park, Haian, Jiangsu province

Hcadquartcrs address:No.35,Lane80o,Meijiabang Road,

songjiang District,Shanghai Shuanggao BuildingTel:+8621-65897888 +8621-65895437

E-mail: yyf@ guanhou. com Mob.; +8618964876877

micro-blog